Understanding LED transparent screen

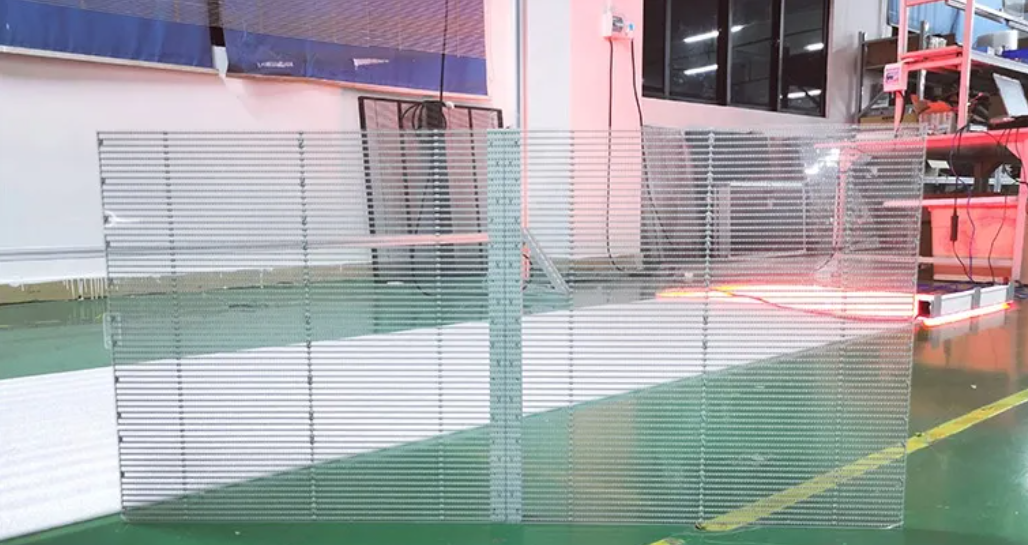

LED transparent screen display often refers to the transparent screen with hard light bar, which has the characteristics of light and thin, transparent, and transparent and beautiful playing images. It is an effective extension and expansion of the application of LED display products, mainly used in architectural glass curtain walls, windows and other fields.

LED transparent screen display technology principle

The principle of the LED transparent screen display is the same as that of the conventional LED display. The power is provided by the LED power supply, the control system is responsible for conveying instructions, the driver IC provides the display program, and the LED lamp beads are responsible for displaying various information. It is fixed into a complete LED transparent screen unit through the PCB board and the bottom shell mask, which is what we call the box. However, the box panel adopts innovative technology in structural design and related processes. The light bars are designed as hollow structures one by one, just like the shutter structure, which makes the screen transparent, which is the biggest difference from conventional LED displays. s difference.

LED transparent screen display production

The main components of the LED transparent screen are: light board, power supply, control card, and connection light. The main process of LED transparent screen display production is as follows:

1. Chip technology

Paste the LED lamp beads on the light strip of the PCB version to form pixels. We often say that the pixel pitch is the distance between two adjacent lamp beads, and the resolution is the number of lamp beads per unit area. Pay attention to the aspect of the lamp when patching, don't paste it backwards, and don't paste it less.

2. Solder

Check whether the patch on the light board is out of light or weak soldering, etc.

3. Installation of box frame

Align the finished light board and the box frame, and screw in the screws. The production process of LED transparent screen driver board is as follows: patch, driver cable connector, power connector welding, capacitor welding, driver IC welding.

4. QC testing

The driver board is inserted into the light board, welded, and QC inspection is carried out. Including the lighting aging test for 72 hours, including 48 hours of red, white, blue, and green lights, which are used to check for weak welding or necrotic lamp beads for repair and replacement. Play the video content for another 24 hours. If you find color casts and inconsistent brightness, you will also make balance adjustments. Ensure that the LED display is perfectly presented and runs stably before shipment.

How much is a square LED transparent screen display

How much is a square meter of LED transparent screen display? In fact, it refers to the price of the screen body. According to market surveys, the price of LED transparent screen body is mostly concentrated at 5,000~10,000 yuan/㎡. The main factors affecting the price of LED transparent screens are as follows:

1. Model spacing

In the case of the same material, the smaller the pitch, the higher the price of the LED transparent screen. The pixel pitch is 7.81mm and 10.4mm, and the pixel density is 16436dot/m² and 9246dot/m² respectively. That is to say, one square meter of HY-7.8 screen needs to use 16436 lamp beads. The more lamp beads used, the higher the cost. Therefore, in the LED transparent screen display project, the cost of lamp beads accounts for about 60%.

2. Lamp bead brand and model

Choose the right brand of lamp beads according to your own needs. And the model and use of the lamp bead are also very important. If your LED transparent screen is used for display in an indoor environment, in fact, the brightness of 1000~1500cd can meet the demand; if it is a semi-outdoor environment, the brightness is 2000~3500cd; if it is a full outdoor display, the brightness is 4000~5500cd. Be sure to choose the brightness according to your own display needs and the use environment. In general, brighter lamp beads are more expensive.

3. Structural process

At present, LED transparent screens are divided into two types: side-emitting and front-emitting. The former adopts the process of front-facing lamp beads, and the lamp beads are welded to death, and the display consistency is good; the latter adopts the method of side-emitting lamp beads, which is applied in the engineering field. Plug and unplug. The prices of the two screens will also be different.

Other costs include: power supply, driver IC, accessories (wiring, power distribution cabinet), transportation, and installation costs.

English

English Spain

Spain Russia

Russia